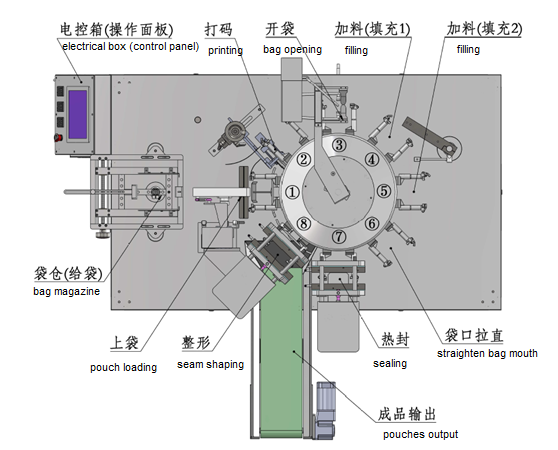

station 1, pouch loading

the pouch storing magazine, the vertically moving suction shaft, the rotary clamps, the pick and place gripper should all be in centered alignment. The pick and place gripper and the vertically moving suction shaft should be accurately adjusted in both timing and positioning. For instance, when the pick and place gripper is moving to grasp the pouch, the rotary clamps should enclose, and when the vertically moving suction shaft reaches its lowest position, it should release the vacuum suction. when the pick and place gripper aligns with the rotary clamps in a parallel position, the rotary clamps should open, upon reaching the highest position, where the vertically moving shaft makes contact with the pouch, it should activate the vacuum suction.

Common machine failures include a low pouch placement rate, which encompasses issues such as the inability to suction the pouch, the rotary clamp failing to secure the pouch resulting in a collision of the bag edge, and occasional instances of double pouches being suctioned.

Solutions: If there is no dirt on the suction pads, and the vacuum suction is activated, with correct suction timing and position, which can be confirmed by manually touching the air tube, then the issue arises from the magazine. Initially, adjust the magazine to allow the pouches to move freely in the vertical direction. The magazine is composed of lateral plates and an adjustable bottom plate. Adjust the free space between them based on the size, hardness, and softness of the pouch material, maintaining a clearance of 4-10mm. An air tube in the lateral plate blows air to ensure the necessary separation between pouches for easy retrieval.

As for the issue of collisions between the rotary clamps and the pouches, assuming there is no deformation of the pouches, please inspect the opening width of the clamps. Typically, it should be around 18mm. If it is too narrow, adjust the rod connected to the clamp opening cam, tighten the screw securely after the adjustment. Additionally, ensure that the pick-and-place gripper aligns with the rotary clamps when it is in a parallel position with the clamps.

When encountering issues where the pouches are positioned with one shoulder lower than the other side, this can be resolved by adjusting the screws connected to the adjustable bottom plate of the magazine. Screw forward to raise it up and backward to lower it down. Also, pay attention to the rotary clamps during pouch clipping. If the pick-and-place gripper releases the clip too early, causing the pouch to fall, it means the pouch suction shaft is engaging too soon. In this case, raise the time setting from 195 to 200. Conversely, if the pick-and-place gripper is too slow to release the clamps, leading to dragging, lower the time setting from 195 to 190. After these adjustments, the bag should neither fall prematurely nor be dragged, ensuring proper positioning. note: After each adjustment, operate the machine in step mode to prevent potential collisions.

At the sealing or shaping stage, there is often a phenomenon of bags falling. Solution: Check if the indicators on the machine clamp body are consistent when switching to different pouch sizes. If they are all biased to the left or right, adjust the four internal hex screws on the vertically moving suction shaft. Move the entire pouch magazine to ensure that each pair of machine clamps consistently holds the pouches. The indicators on the machine's clamp body should remain consistent after pouch replacement. If there is a significant discrepancy following pouch replacement, it is necessary to replace both the clamps and the filler nozzle. After each replacement, operate the machine in step mode to prevent collisions.

station 2, printing

If the coding on the pouch is unclear or absent, ensure that the pouch successfully passes through the coding station. If it does, adjust the position and angle of the printer. Additionally, confirm that the printer is heating up properly, and the duration is accurate, typically lasting between 0.2-0.6 seconds. Check for proper contact between the characters and the rubber, and make adjustments to the air cylinder to enhance coding clarity.

station 3, bag opening

Please confirm that the suction is activated and the timing is correct. verify whether there is suction by removing the air tube and sensing with the finger. During the intermittent pause in the rotating motion, the opening grippers initiate clipping, and the suction begins. The suction remains active until the rotary machine clamps begin to retract. At this point, the opening gripper starts to separate, and the suction is discontinued. Ensure that the suction pads maintain complete contact with the pouch (on both sides) to prevent any vacuum leakage. The suction pads should be positioned between 0.2 and 1cm below the pouch opening.

check for any damage to the suction pads, with suction pressure applied, adjust each tube clamp so that, when the suction pads are closed, the upper edges align precisely with the opening of the pouch, remaining essentially level, and positioned at the center of the pouch. there should be minimal to no significant gap when the pads are closed.

coordinate the air blowing process so that the timing, angle, and intensity align with the moment the pouch is being pulled apart. The blowing should commence precisely at the moment of clamp separation, and the intensity should be appropriately calibrated to match the characteristics of the pouch material. fine-tune the air blowing intensity using the small filter located underneath the machine.

station 4, filling

station 5, filling

Time adjustment is crucial, typically occurring during the pause of the rotary clamp. At this moment, the number displayed on the screen is the optimal time—neither too early nor too late. Common issues include no filling or continuous filling. Check for damage to the proximity switch by manually approaching the aluminum block to it; the light should turn on, and when moved away, the light should turn off. If not, the proximity switch is damaged. Additionally, use a multimeter to test for a 24V voltage; if absent, the proximity switch is faulty.

Furthermore, power on the machine and observe if the X101 light on the PLC flashes normally to rule out cable or PLC-related issues. The method for adjusting two proximity switches is as follows: adjust the proximity switches and the aluminum blocks so that the light turns off when the two rods in the pouch open it and turns on when unable to open it or only one side is opened. After ensuring no problems with these, check that the Y000 cable of the electronic scale is not loose or experiencing a short circuit. If Y000 has output, examine the intermediate relay using the multimeter to detect the cable between the electronic scale and the intermediate relay. The electronic scale should be in the "waiting for packaging signals" state. If Y000 does not output, verify the timing of the filling. Ensure that the Y000 and common terminals are secure, and the X105 or DC24 is not short-circuited. Confirm that the Y000 light on the PLC is on. If everything is in order but the light is not on, it indicates a faulty point in the PLC.

station 6, straighten bag mouth

station 7, sealing

station 8, shaping, products output

Please confirm that the suction is activated and the timing is correct. verify whether there is suction by removing the air tube and sensing with the finger. During the intermittent pause in the rotating motion, the opening grippers initiate clipping, and the suction begins. The suction remains active until the rotary machine clamps begin to retract. At this point, the opening gripper starts to separate, and the suction is discontinued. Ensure that the suction pads maintain complete contact with the pouch (on both sides) to prevent any vacuum leakage. The suction pads should be positioned between 0.2 and 1cm below the pouch opening.

check for any damage to the suction pads, with suction pressure applied, adjust each tube clamp so that, when the suction pads are closed, the upper edges align precisely with the opening of the pouch, remaining essentially level, and positioned at the center of the pouch. there should be minimal to no significant gap when the pads are closed.

coordinate the air blowing process so that the timing, angle, and intensity align with the moment the pouch is being pulled apart. The blowing should commence precisely at the moment of clamp separation, and the intensity should be appropriately calibrated to match the characteristics of the pouch material. fine-tune the air blowing intensity using the small filter located underneath the machine.

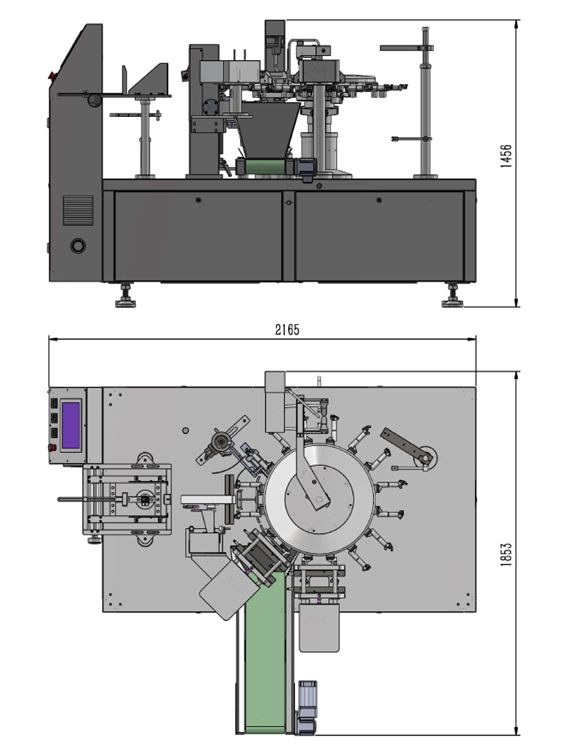

| machine dimensions | 2165×1895×1493mm | |

| machine weight | 1200 | |

| packing speed | 30-55 | dependent on the product |

| pouch sizes | bag width: 100-250mm, bag-length: 150-350mm | |

| voltage | 380V | |

| power load | 3.5 | |

| air displacement (m³/min) | >0.6 | customer provides the compressor |

| minimum air pressure (Mpa) | 0.5 | customer provides the compressor |

Holding down for 2 seconds, a buzzer ring indicates the machine is starting to run. however, scenarios likes these suggest that the machine is not in operation.

To ensure the machine is well-maintained and has a prolonged lifespan, regular inspections, cleaning, and oiling are necessary. Performing these tasks regularly not only helps maintain the machine in good condition but also allows for the early detection of potential defects, effectively preventing major accidents. Remember, daily maintenance should be conducted after cutting off the main power supply and stopping the machine's operation

the following steps require the main power to be turned on.

cleaning process