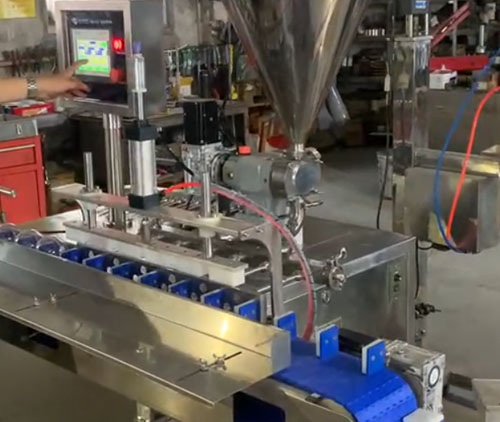

The cream injecting machine comprises a conveying mechanism, a core lateral movement mechanism, a pressure mechanism, a rotor pump filling mechanism, and a barrel stirring mechanism. The equipment is equipped with three sensors: the first sensor controls the precise positioning of the conveyor belt, the second sensor detects the presence of products, and it will not work if the product count is insufficient. The third sensor checks whether the barrel has material. The conveyor belt has limited-position pushers, and each pusher can hold 3 egg rolls or one cream puff. Six pusher blocks form a group, and one group is injected at a time.

Production capacity:40pcs/min

Dimensions:2800×1000×1500mm

Weight:400Kg

Materials:316SS(food contact parts),304SS(machine shell)

Power supply:220V

Power load:2Kw