These food packaging machines are equipped with an advanced PLC computer control system, ensuring simple and convenient operation. They utilize control systems from internationally renowned brands to automate bag-making, metering, filling, inflation (deflation), sealing, cutting, counting, and coding operations. Custom hole punching is also available upon request.

An intelligent photoelectric control device ensures the integrity of bag patterns. Bag pulling is achieved through a stepper motor drive and color mark positioning, delivering stable performance, easy adjustments, and accurate detection.

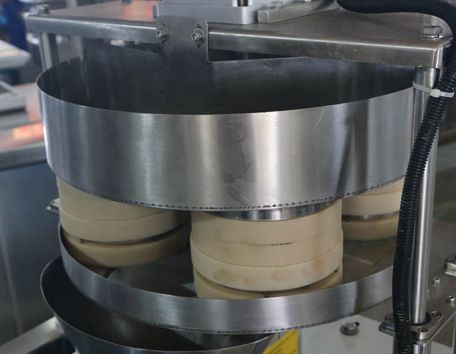

The entire machine is constructed with 304 stainless steel components, meeting food and pharmaceutical hygiene standards.

This machine can be tailored to produce pillow-style bags, stand-up bags with corner folds, hole-punched bags, and linked packages ranging from 5 to 12 bags.

It features an intelligent temperature controller for precise temperature control, ensuring beautiful and flat seals. It also includes comprehensive automatic alarm and protection functions to minimize losses.

The measuring system employs a 10-bucket electronic scale controlled by a microcomputer, providing highly accurate measurements. The machine primarily uses digital combination calculations to generate numerous eligible combinations from multiple weighing buckets and selects the combination closest to the target weight.

Advanced design ensures that the machine is easily adjustable, operable, and maintainable across various industries. It can be paired with various automatic measuring devices from both domestic and international sources.

This machine can package a wide range of materials, including multi-layer composite films, polyester/polyethylene, polyester/aluminum foil/polyethylene, polyester/aluminum-plated/polyethylene, paper/polyethylene, and more.

Applications: Suitable for packaging high-precision and fragile granular materials, such as puffed food, crispy rice, potato chips, snacks, candies, pistachios, sugar, apple slices, dumplings, chocolates, pet food, small commodities, and more.

| Model type | K420 |

| Bag length | 80-300mm |

| Bag width | 80-200mm |

| Film width | 160-420mm |

| Packing speed (bags/min) | 10-75 |

| Power load | 2.5Kw |

| Air pressure | 0.65Mpa |

| Air consumption | 100L/min |

| Weight | 500Kg |