Diverse Packaging: Suitable for diverse packaging, one set of equipment can handle packaging for products of different sizes.

Human-Machine Interface: Large touchscreen panel for easy operation.

Memory Menu: Can memorize and store multiple sets of packaging product settings, allowing for quick product switching without wasting time.

Mis-Cut Protection: Prevents mis-cuts to avoid damage and waste of products.

Material-less Standby: In automatic detection mode, the machine automatically enters standby mode when there is no material, preventing the generation of empty bags and minimizing material waste.

Fault Troubleshooting: Automatic fault troubleshooting to reduce time consumption.

Servo Automatic Sensing Feeding: Bag length is set and cut instantly without the need for idle running, saving time and film.

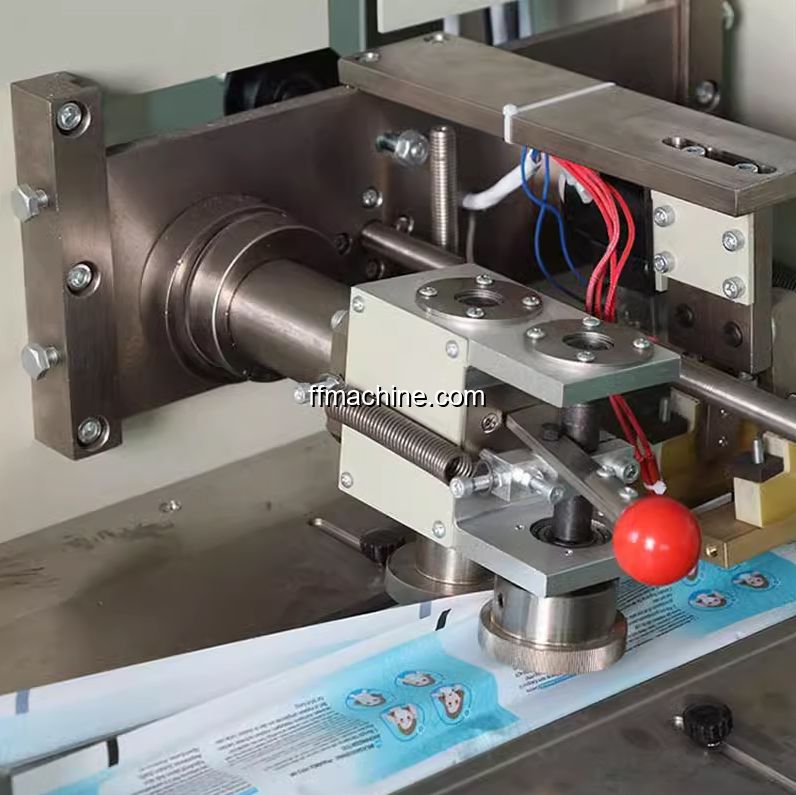

High-Sensitivity Photoelectric Eye Color Mark Tracking: Digital input of the sealing knife position for more accurate sealing.

Independent PID Temperature Control: Better suited for various packaging materials.

All Controls Implemented by Software: Convenient for function adjustment and technological upgrades.

| Model Num | KD-260 fully automatic flow wrap machine |

| packaging material and sizes | pp heat sealable, laminated structural film coated paper, aluminum foil film, aluminum plastic composite film 0.03-0.06mm |

| Machine dimensions | 4100*950*1500 |

| Packing speed | 40-250bags/min |

| Bag length | 60-200mm |

| Bag width | 25-100mm |

| Bag height | 5-45mm |

| Rated voltage, power load | AC220v.2.4KW |

| compressed air pressure | 0.5-0.7(Mpa0 |

| air consumption | >0.36(m3/h) |

| Noise (dB) | low noise.60-70dB |

| Machine weight | 650Kg |

| Motor frequency | 0-50Hz |

| automatic control | auto printing |

| industry standard | GMP |

| Quality certification | ISO9001:2000 CE |