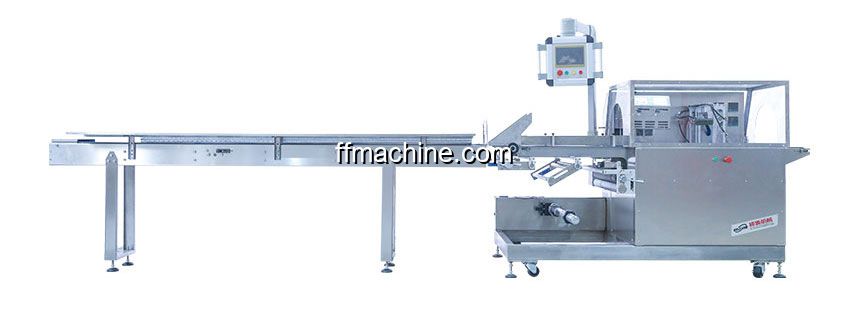

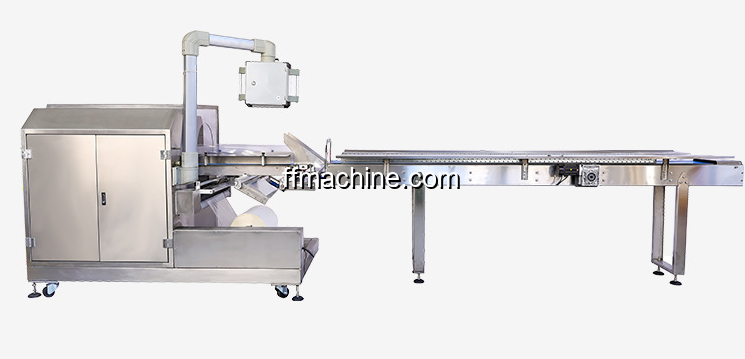

This flow wrap machine is suitable for a variety of vegetables including potatoes, Chinese cabbage, carrots, cilantro, string beans, Chinese yams, white radishes turnip, oilseeds rape romaine, lettuce, chives, water spinach, scallions shallot, celery, onion, ginger, garlic, leeks, sponge gourd, bitter gourd, cucumbers, pumpkins, chili peppers, tomatoes, and corn.

| Packaged item dimensions range | L: 50-900 W: 80-230mm H: 30-150mm |

| Packing speed | 10-45(bags\min) (varies with packed item length and material) |

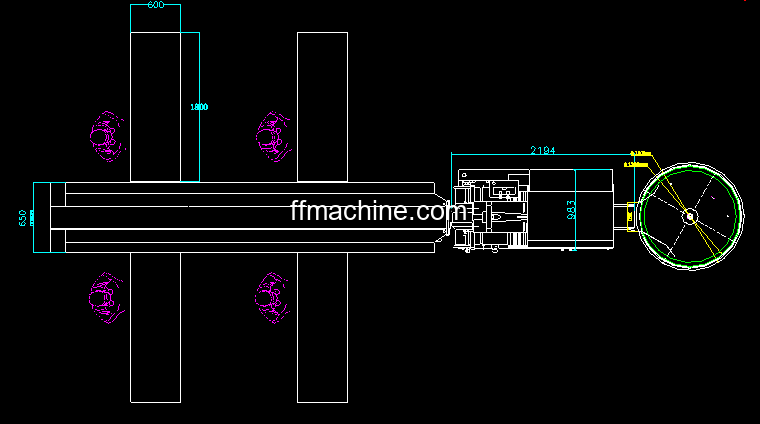

| Machine dimensions | L70000mm W1003mm H1670mm |

| Belt sizes | item feeding belt: 5000 ×240mm broad side feeding belt (2pc) L2600 ×90mm reciprocating belt: L1000mm×250mm output belt L600 ×250mm item loading area depth: 90mm |

| Belt material & thickness | food-grade ware resistant and easy to clean PU thickness 1.8×1.2 |

| Sheet metal | SUS304#2.0,cases 8mm45#steel+2mmSUS304# |

| Support frame material | SUS304#2.0 |

| Packing speed in meters | 5meters (low)-15m(high)/min, variable frequency drive |

| Max film width | 680mm |

| Machine weight | 900KG |

| Power load & voltage | 220VAC\50Hz 3.0KW |

| Film thickness | 25-60um |

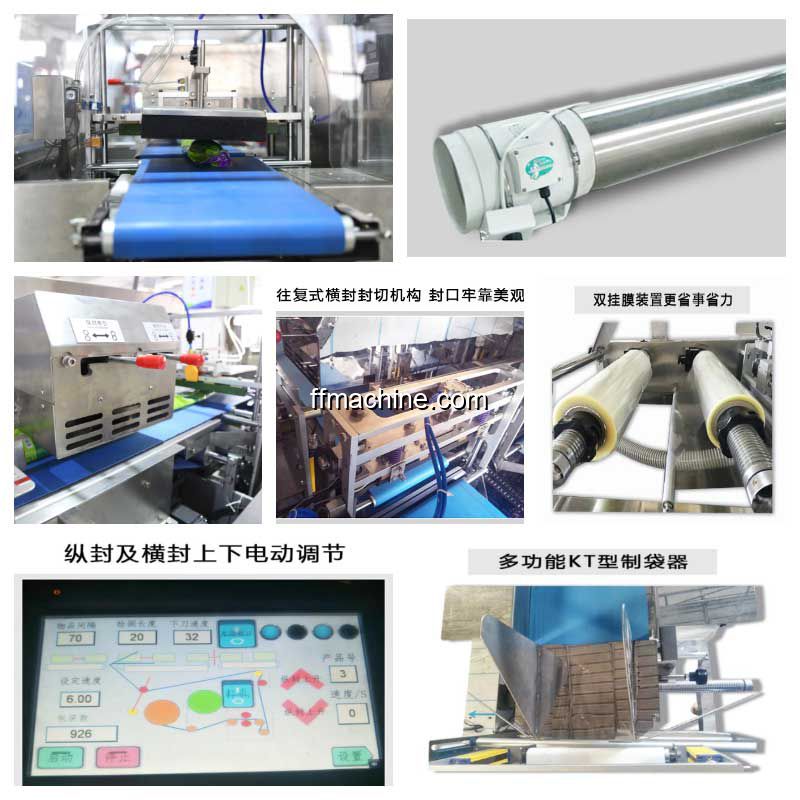

| Applicable film type | Bopp/pe、Cpp/pe、 Cpp/PA、BOPP、CPP frog resistant film or heat sealable film |

| Film rolls | 2rolls at the same time |

| horizontal sealing electric regulation height | 150 |

| Film roll diameter | 320mm |

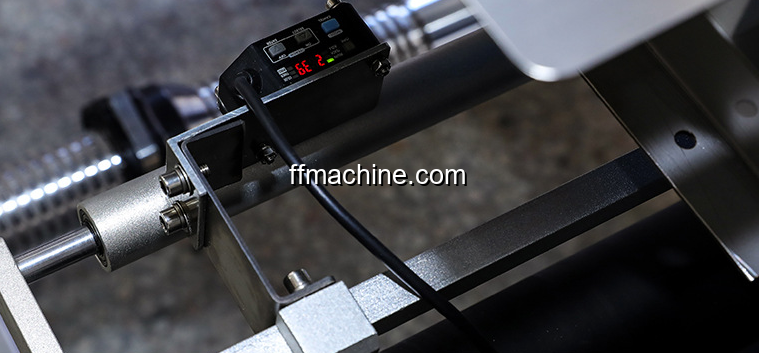

| Wasted film collection unit | 6-12mm diameter wasted films will be collected into bin to prevent them from being packed in final products |

|

Four station reciprocating hole punch device |

Fast hole-punching speed, high efficiency, and the punching speed is synchronized with the packaging process to prevent tearing caused by film pulling during punching. Four holes are punched at intervals of 60mm, with hole diameters ranging from 6-12mm. For packaging Chinese cabbage, 10-12 breathable holes can be punched. |