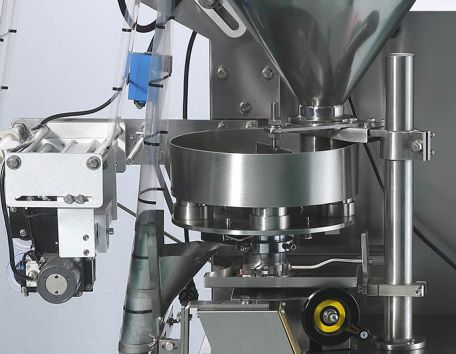

Utilizing an advanced microcomputer touchscreen interface, the human-machine interaction is intuitive and user-friendly. the food packaging machine employs an internationally renowned brand for the control system, capable of automatically performing processes such as bag making, metering, filling, inflation, sealing, cutting, counting, and coding, with the ability to be customized to meet specific customer requirements.This machine offers multiple packaging options, including back sealing, three-side sealing, and four-side sealing. The cutting method can be chosen from a flat knife, serrated blade, or dotted line.The volumetric measurement is achieved through a stainless steel measuring cup with adjustable capacity, ensuring both precision and ease of operation.The intelligent photoelectric control system guarantees the integrity of packaging patterns. Bag pulling is controlled by a step motor and color mark positioning, ensuring stability, ease of adjustment, and accurate detection.The entire machine, including components in contact with the product and the casing, is constructed using 304 stainless steel, complying with food and pharmaceutical hygiene standards.The advanced design ensures that this machine is suitable for various industries, offering easy adjustment, operation, and maintenance. the food packaging machine can be integrated with various automatic measuring devices from both domestic and international sources.

| Model Number | K100 | K300 |

| Bag length | 30-150mm | 50-300mm |

| Bag width | 25-120mm | 90-190mm |

| Film width | 60-240 | 160-380 |

| Bag capacity | 5-100mL | 50-500mL |

| Packing speed | 30-60 | 30-60 |

| Power load | 1.6Kw | 1.6Kw |

| Voltage | 220V | 220V |

| Overall dimensions | 760× 1380× 1700mm | 900× 1800× 2040mm |

| Weight | 300Kg | 500Kg |