Fast molding, three-dimensional heating/surrounding speed molding, vacuum pump and vacuum tank quickly form the bottom to increase thickness yield.

Good vacuum effect, upper-middle-lower vacuum extraction, fast speed, high vacuum degree, nanotechnology for one-second sealing, reducing thermal energy loss. The heating plate locates vertically for sealing, saving electricity, ensuring smooth sealing, clear patterns, and good sealing effects.

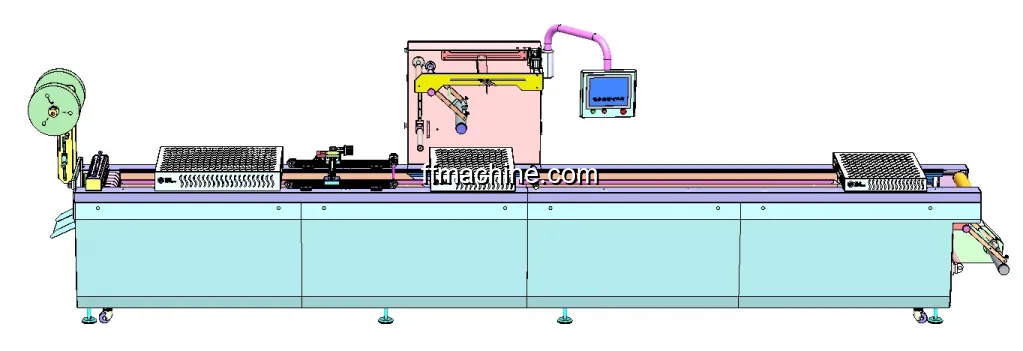

304 stainless steel, all welded and formed using stainless steel, and through double-sided grinding and mounting, there is no phenomenon of film deviation. The machine has high precision, stability, and durability.

Stable frame, the whole machine is made of stainless steel, with enlarged dual industrial excellent electric pumps. The cutting blade works independently in a fixed direction, and the blade is treated specially for durable sharpness.

Dual-line control panel, adjustable vacuuming, sealing, and cooling time, stable performance, intelligent control, and simple operation.

Intelligent brake system adopts high-end ABS anti-lock braking system used in large buses, ensuring that the color film is not displaced, with high precision, and the appearance of the packaged product is beautiful.

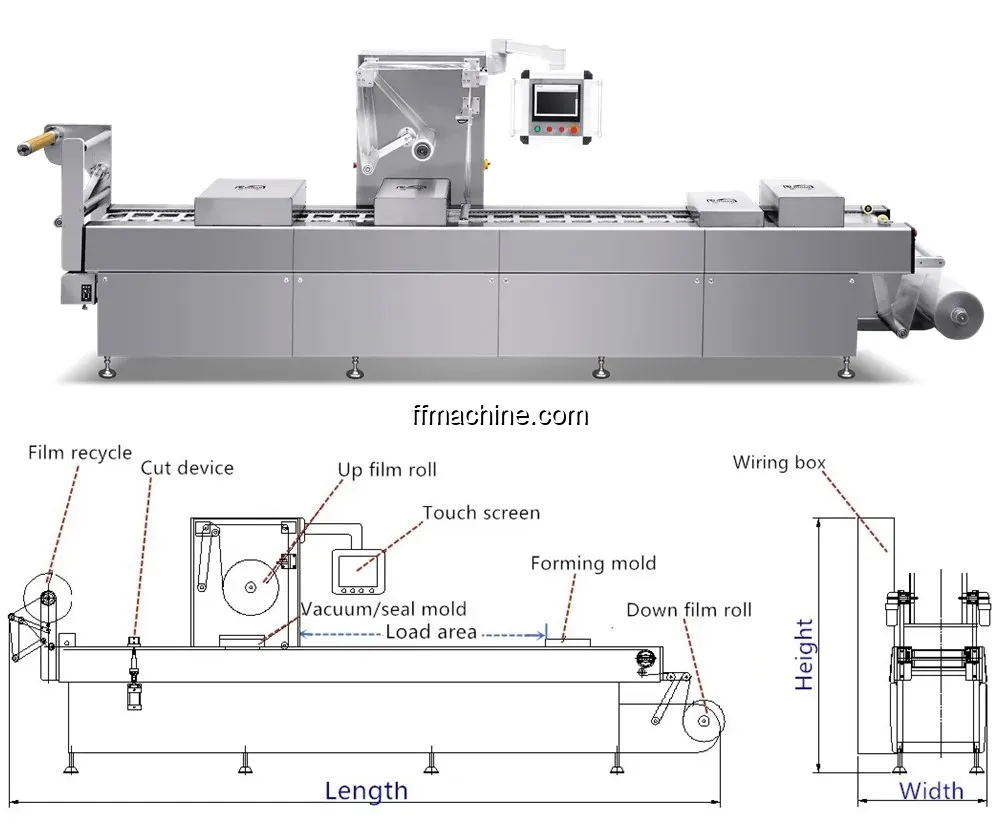

| Model | DLZ-320T |

| Material | 90% food grade 304 stainless steel + 10% aluminium alloy |

| Film type | Flexible package with serrated edge |

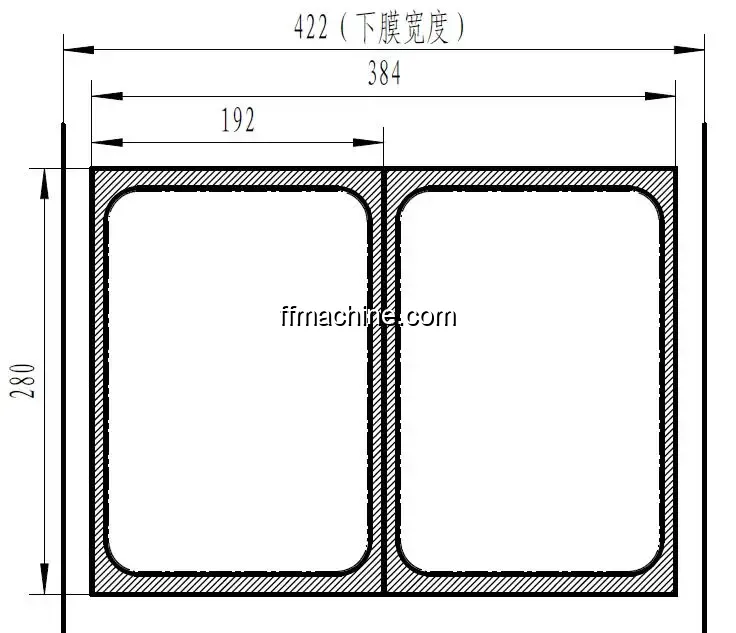

| Film width | 290/322mm |

| Step length | 230-320mm |

| Air pressure | Pressure 0.6-0.8Mpa, supplied by air compressor which has min 200L gas tank |

| Voltage | 380V/415V/460V 50HZ/60HZ 3Phase |

| Power | 15-18KW |

| Language | English/Spanish/Russia/Chinese/Arabia for options |

| Function | Forming container, put food by hand, vacuum, seal, cut |

| Vacuum pump | Busch 100m³/h |

| Overall size(L*W*H) | 5200*900*1880mm |

| Weight | 1700KG |

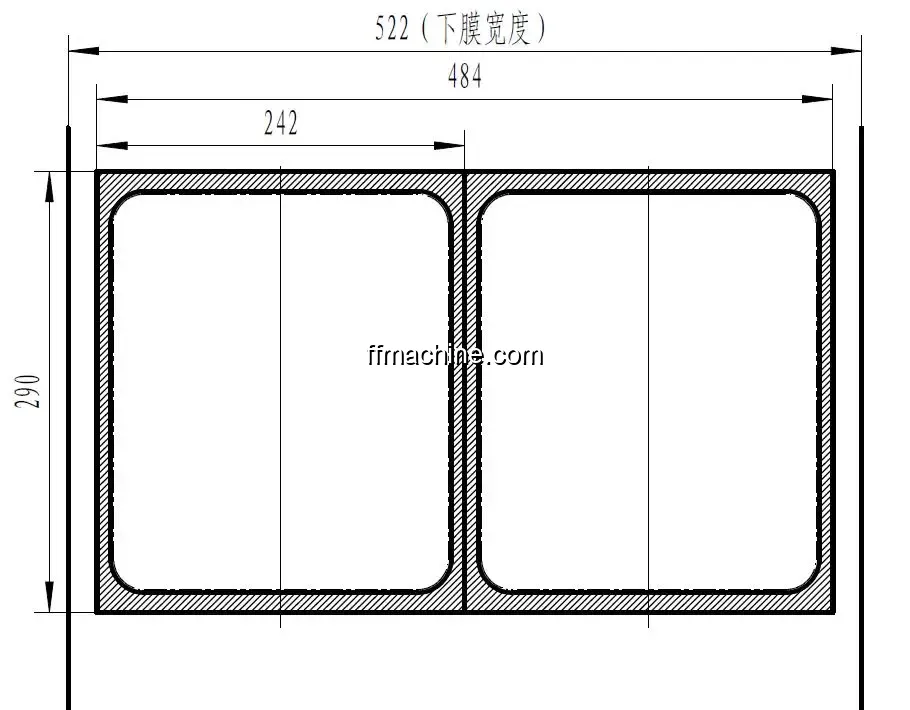

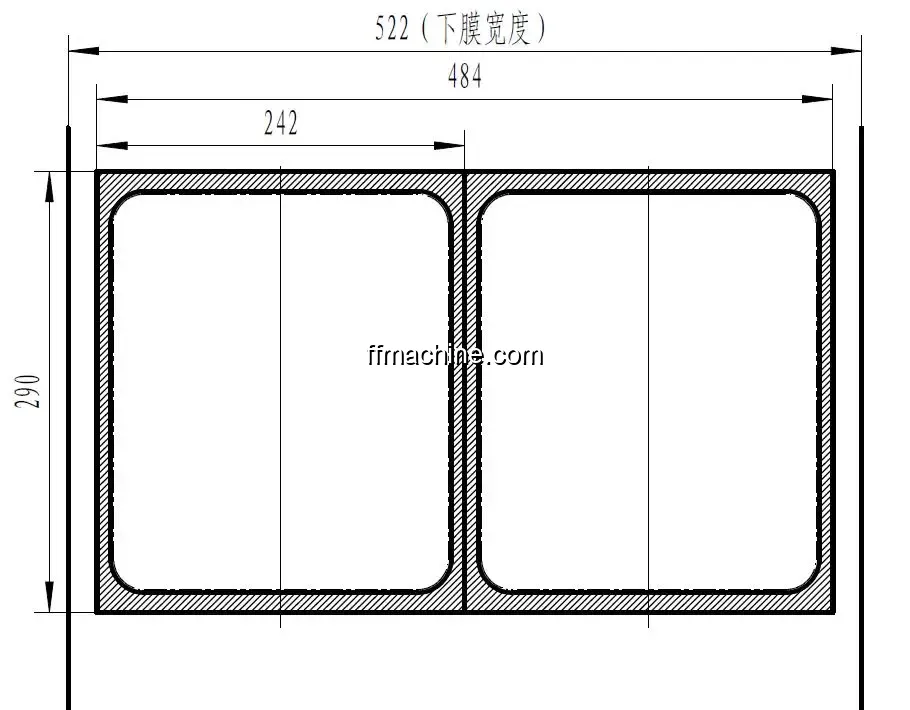

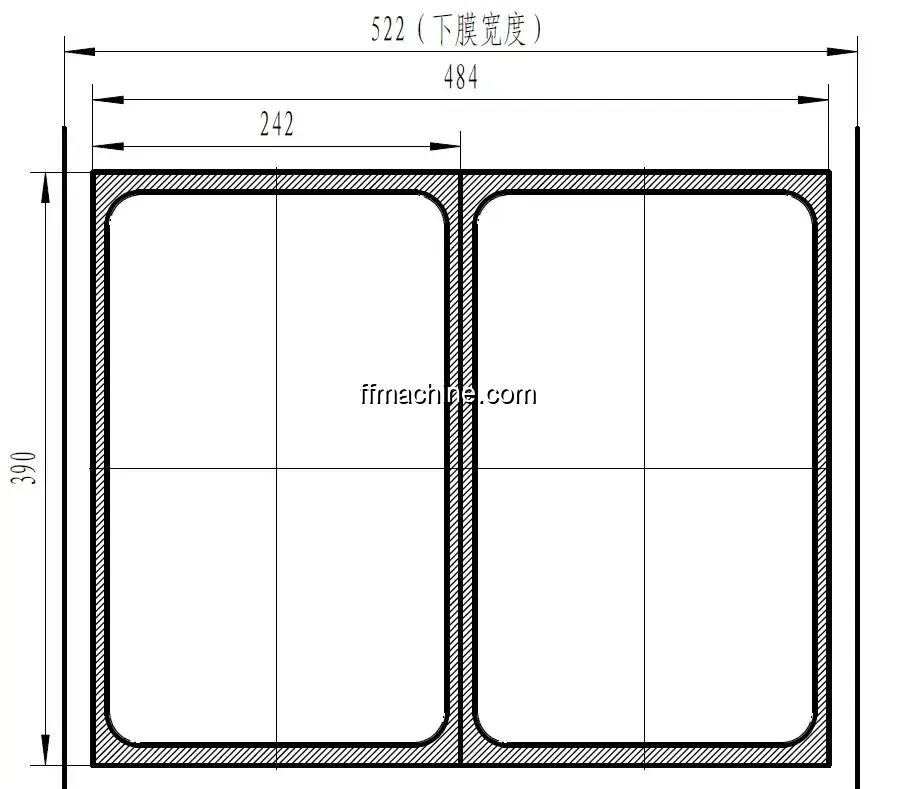

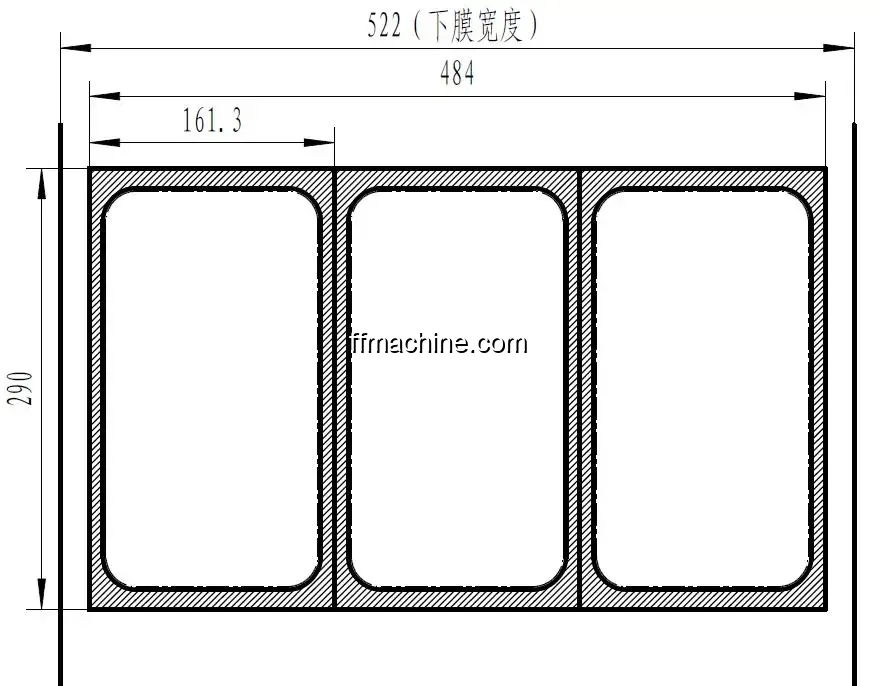

| Mold number | 1 mold for standard machine. Able to support maxi 3 molds |

| Cut system | Cross/rolling cut |