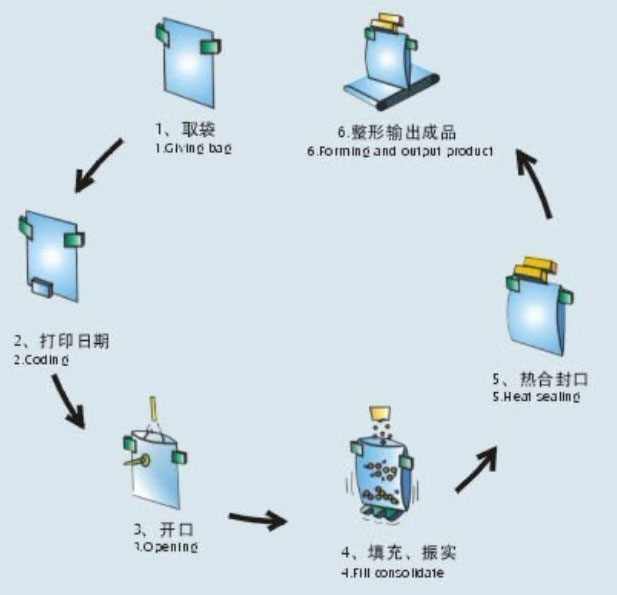

Premade pouch filling machine have replaced manual packaging, enabling packaging automation for large scale enterprises as well as small or medium-sized businesses. The operator simply needs to place several hundred pre-made pouches into the bag magazine of the equipment at once, and the mechanical gripper of the device will automatically pick up the pouches, print the date codes, open the pouches, signal the measuring unit for measurement and dispensing, seal the pouches, and then output them.

Customers can also incorporate additional detailed functions such as emergency stop when opening the door, automatic card insertion, abnormal discharge, based on their product packaging requirements. The entire packaging process requires no manual intervention, effectively enhancing the company production efficiency, saving on labor and management costs, and significantly reducing expenses.

The pre-made pouches' applicability is extremely broad, as they are made from paper-plastic composite, plastic-plastic composite, aluminum-plastic composite, PE films composite and more, After integration with different measuring and dosing systems, the pre-made pouch packing machine becomes a multi-functional device.

The pre-made pouch packing machine adopts an advanced PLC combined with a POD (touchscreen) electrical control system, features a user-friendly human machine interface for easy operation. It is also equipped with a detection device that can prevent the filling mechanism from operating when the machine detects the absence of packaging material or if the packaging bag is not open, thus reducing pouches and materials wastage. The machine utilizes a variable frequency speed control device, allowing for flexible speed adjustment within a certain range according to actual production needs. The machine allows for quick changes in bag sizes. The width adjustment handler of the bag magazine can be easily and swiftly adjusted, allowing efficient operation. During the specification adjustments, adjusting only one bolt can lead to the conversion of all 10 sets of mechanical claw specification. This process is simple and convenient. The normal service life exceeds 10 years.