The piston pump employs pneumatic force to drive the reciprocating motion of the cylinder piston, drawing the material to be packaged into the pump body. The machine controls the direction valve, then dispenses the material from the pump body into the pouch. The liquid may be pure water, a viscous gel-like substance, or contain particles. It can be used in conjunction with a barrel equipped with a stirrer, and the barrel can also be fitted with an electric heating pad to prevent the fluid from solidifying at room temperature. The piston's advancement depth can be manually adjusted to control the material quantity, or a servo motor can be installed to regulate the filling volume. Typically, a touchscreen separate from the packaging machine is included, often associated with a piston pump, and for materials with high viscosity and large particles, a rotary pump can be utilized.

Screw feeding is a method that utilizes a servo motor to control the rotation cycles and speed of the screw, allowing the powder to flow like water into the filling channel. In powder packaging machines, especially those designed for small-dose powder packaging ranging from 5 to 5000 grams, precise control of the screw's rotation cycles enables accurate regulation of the filling weight. Of course, the basic criterion for the measurement accuracy of powder packaging machines is whether the volume of each screw pitch reaches the same specification. Additionally, factors such as pitch, outer diameter, bottom diameter, and the shape of the screw blades all play a role in influencing packaging precision and speed.

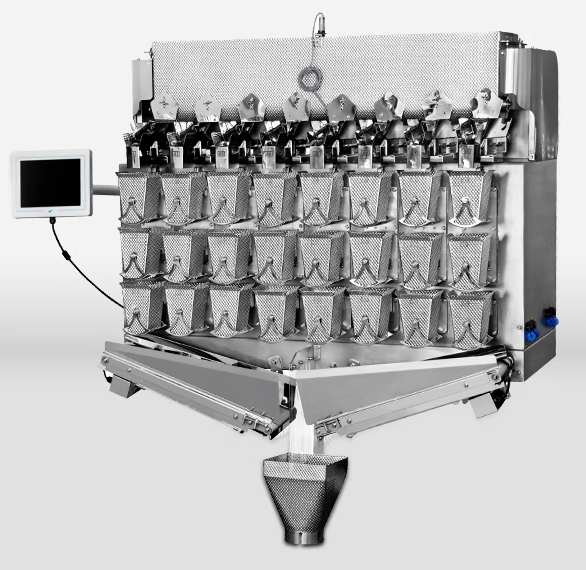

Suitable for bulk materials with a low target count, such as bell peppers, fruits, jelly, candies, and large-shell nuts. please also refer to how multihead weigher works?

When the measured material or the measured quantity undergoes a change, it is necessary to replace a set of measuring cups with the corresponding volume. The corresponding measuring device must be equipped with various measuring cups of different volumes for replacement. To address the limitation of cup replacement, an adjustable volume measuring cup device is employed, which can to some extent overcome the need for cup replacement. The measuring cup is composed of upper and lower cylinders, and changes in volume are achieved by adjusting the relative positions of the two cylinders. Adjustment of the spacing between the upper and lower cylinders of the measuring cup can be done manually or automatically. Manual adjustment involves the manipulation of the adjustment mechanism by operators based on changes in measured values detected during the packaging production process or variations in material density. please refer to the article volumetric cup filler to better understand how it works.

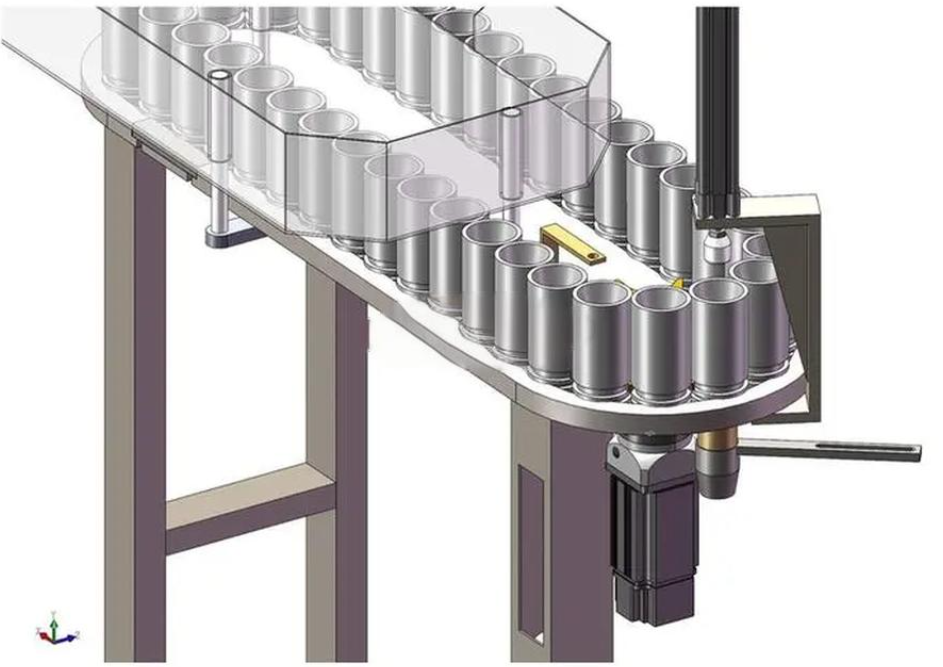

On the workstation, the operator manually inserts the materials to be packaged into cups arranged in a circular pattern. The queue of cups rotates around to the top of the machine, and a pneumatic piston is used to push the material from the cup into the bag. This process is commonly used for packaging items like bread or eggs.

Suitable for meat chunks with soup or other snacks, this system involves manual weighing, where the ingredients are hand-fed into a bowl. Equipped with an independent motor, it operates in conjunction with the packaging machine. Upon activation, it lifts the bowl above the packaging machine and releases the contents into the bag. The bowl can be made of food-grade PP material or stainless steel, typically with a capacity of 1.5L or 2.5L.

A precision sensor with high accuracy, rapid material dosing capabilities, and an adept defense against blockages characterizes this system. Tailored for irregular and low-fluidity products like pickled mustard greens, pickled vegetables( sauerkraut), and fresh seafood, it boasts an intelligent malfunction alarming system for prompt issue identification. Maintenance is streamlined for user convenience, facilitated by a three-layer hopper layout optimizing space utilization. The inclusion of a belt conveying system, hopper scrapers, and augers addresses challenges posed by sticky materials. Encased in a stable and precise aluminum shell, this design ensures metering stability.