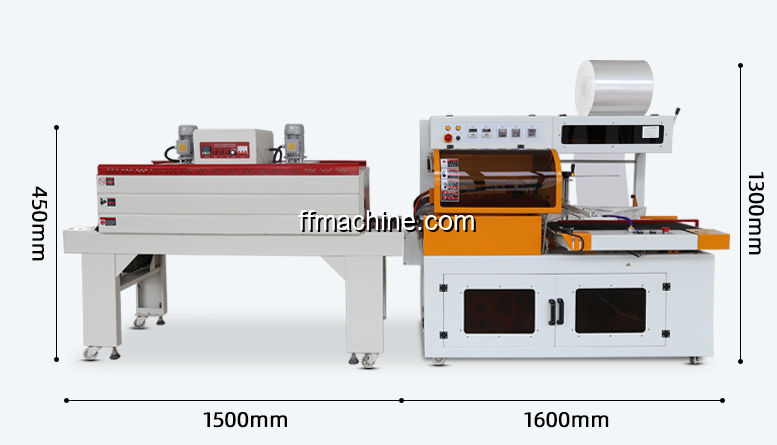

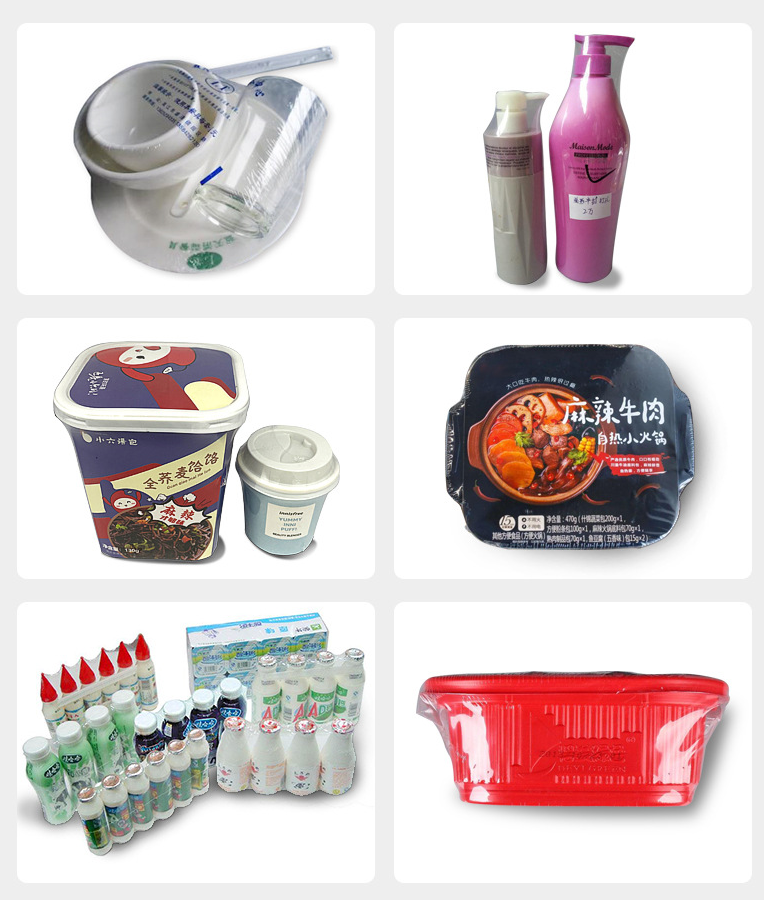

| Sealing cutting method | L type fully enclosed |

| Power supply | 380V/50-60Hz/3phase |

| Max packing speed | 35bags/min |

| Bag height | ≤125mm |

| Bag width | ≤350mm |

| Bag dimensions | H+L≤400mm L+H≤480mm |

| Film type | POFfoled film |

| Max film roll | 530mm(width)×280mm(outer diameter) |

| Power load | 1.5kW |

| Workstation height | 780-850mm |

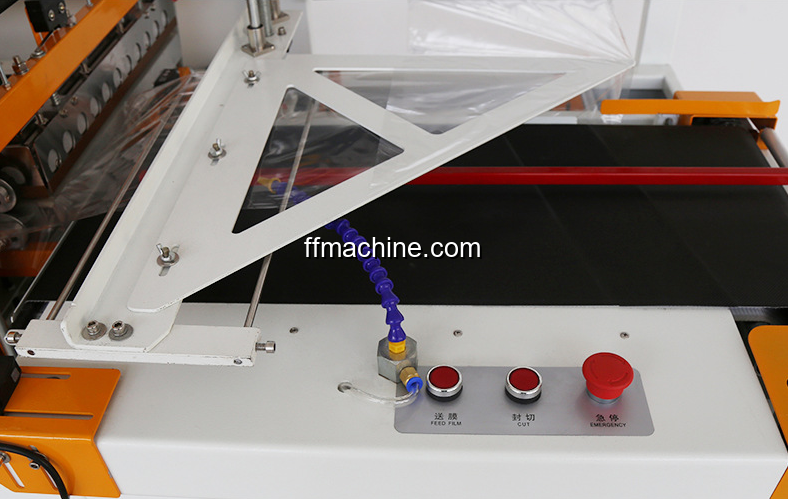

| Air pressure | ≤0.5MPa(5 bar) |

| Sealing cutting system | Constant temperature, free of smoke and odorless |

| Construction material | Carbon steel |

| Weight | 300kg |